Introduction

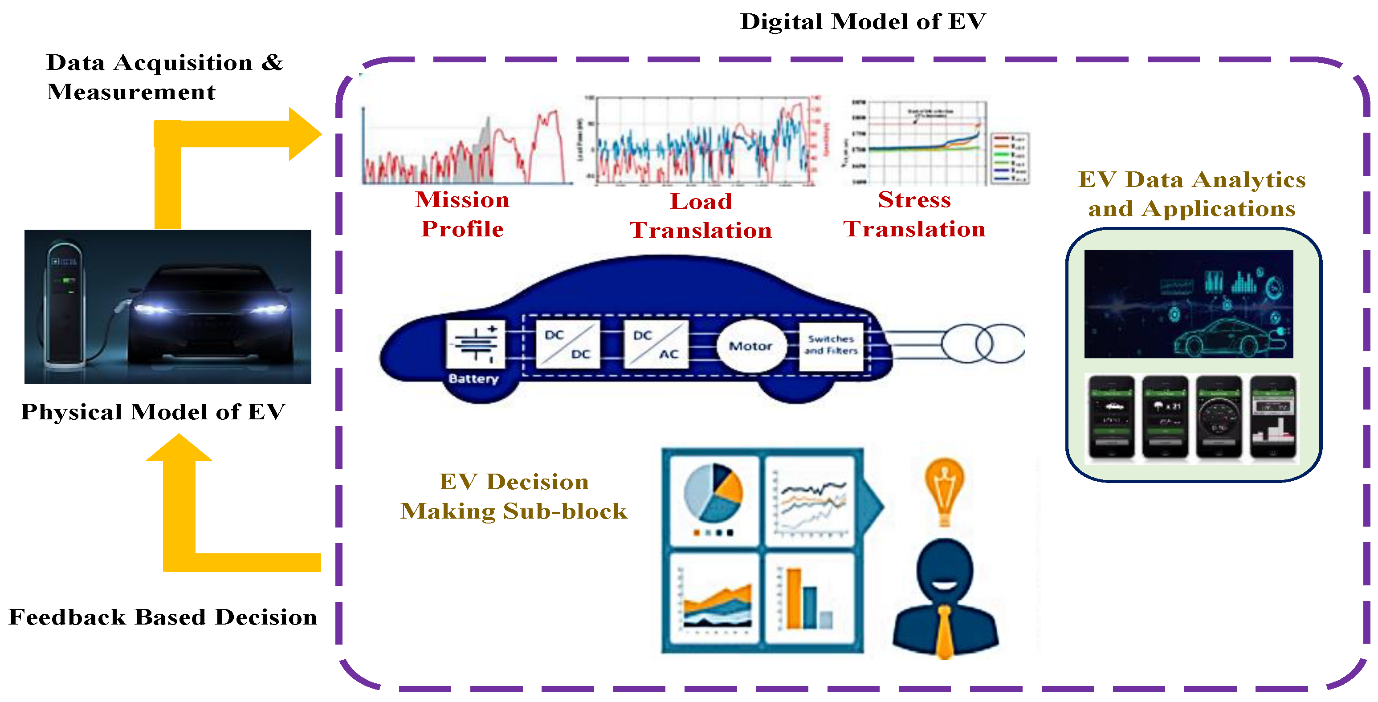

EV Laboratory from Embesys empowers institutions with a turnkey solution for hands-on Electric Vehicle (EV) learning. Designed for skill building, research, and innovation, it transforms campuses into EV Centres of Excellence (CoE), enabling real-world experiments on EV subsystems to equip students and professionals with future-ready e-mobility expertise.

Objectives of Our EV Lab

- Bridge academic learning with industry-ready skills in electric mobility

- Experimental Platforms for EV Technologies: Comprehensive setups for learning, diagnostics, and evaluating EV performance

- Hands-On Skill Development: Practical training on motors, batteries, inverters, and charging systems

- Safety-Compliant Infrastructure: A secure, standards-based environment for safe experimentation and training

- Simulation-Integrated Learning: LabVIEW-enabled experiments for monitoring, control, and advanced data analysis

- Curriculum-Aligned Modules: Tailored to support AICTE, DST-FIST, and Industry 4.0 academic and research programs

- Scalable and Modular Design: Expandable framework for future research in fast charging, IoT diagnostics, and battery emulation

- Holistic approach: ensures students, researchers, and professionals gain both theoretical insights and practical expertise

Advanced Experimentation & Monitoring

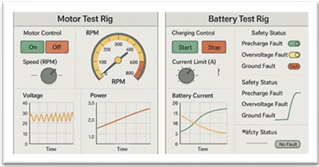

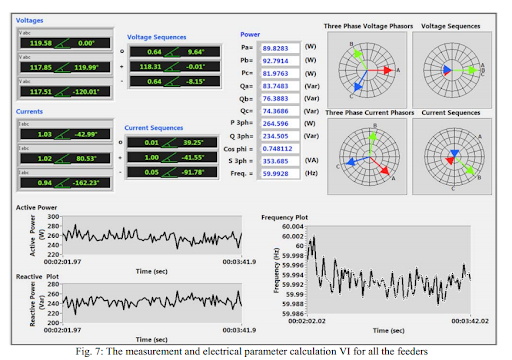

LabVIEW-Based Experiment Logging: Real-time parameter plotting, waveform visualization, and safety limit detection.

Protocol Stack Expansion (CAN + UART): Seamless integration and testing of additional sensors and controllers with standard EV components.

LAB RESOURCE WE OFFERED

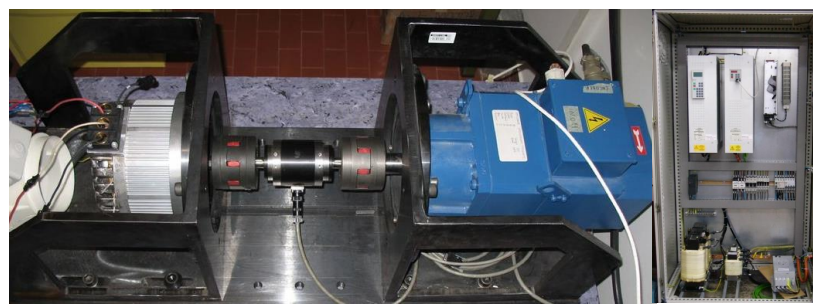

Motor–Dynamometer Test Bench

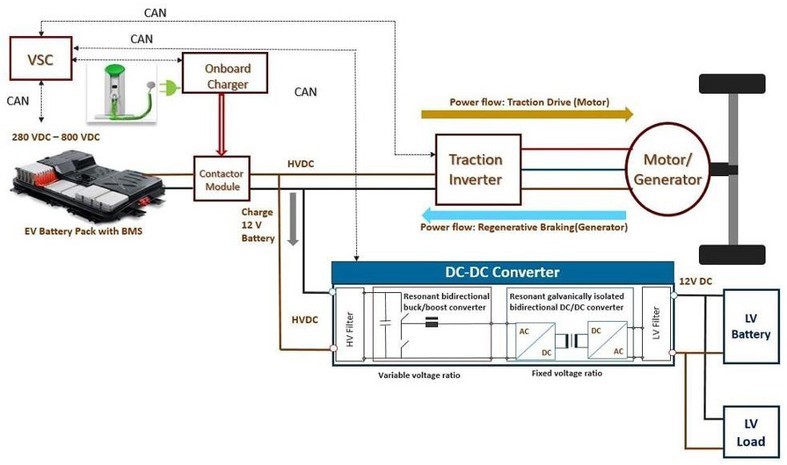

A modular BLDC Motor–Dynamo test setup for EVs that supports motoring and regenerative modes, closed-loop control, and HIL profiles. It measures torque, speed, voltage, current, efficiency, and thermal behavior in real time, with data logging, safety interlocks, and CAN/UDS diagnostics for ECU/inverter testing.

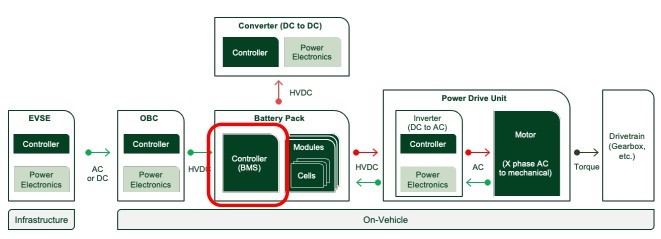

Battery Pack with Charging Station

The ALIARO Battery Cell Simulator (BCS) tests Battery Management Systems (BMS) by simulating actual battery cell behaviour. It allows engineers to verify BMS functions including voltage, current, and temperature monitoring, cell balancing, fault detection, and safety protocols.

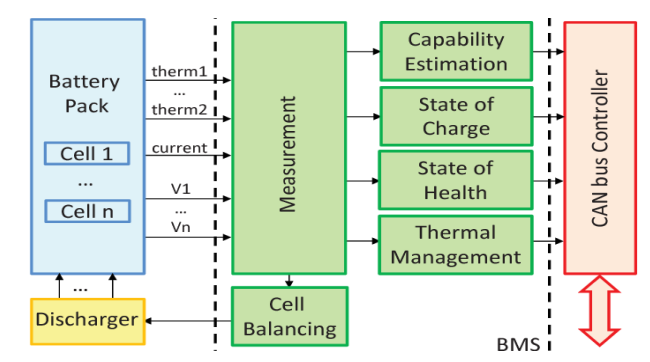

Battery Cell Simulator

The ALIARO Battery Cell Simulator (BCS) is a device that tests Battery Management Systems (BMS) by simulating the behaviour of actual battery cells and their sensors. It allows engineers to verify crucial BMS functions including monitoring, balancing, and safety protocols.

Battery Management Systems

Operate and monitor battery modules and cells for 48V, plug-in hybrid, and battery electric vehicles. Ensures performance optimization and maximum range while providing safety-critical system oversight.

EV Charger Tester

Modular test setup for EVs supporting motoring and regenerative modes, closed-loop control, and HIL profiles. Measures torque, speed, voltage, current, and efficiency with real-time monitoring and data logging.

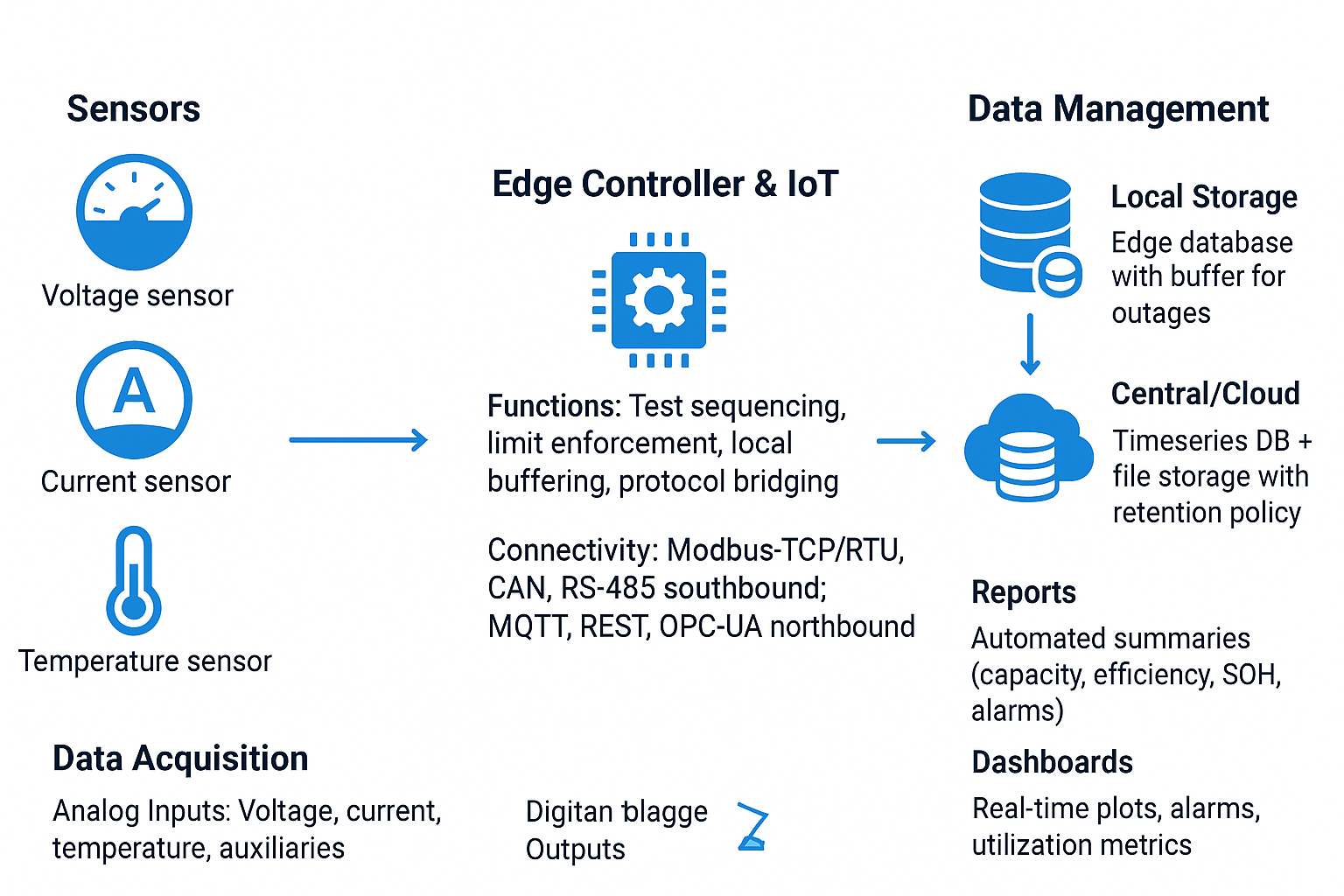

IOT CONFIGURATION

Multi-sensor platform with analog/digital I/O for data acquisition. Edge controller enables local buffering, protocol bridging, cloud/local storage, real-time dashboards, automated reporting, and alerting.

NI Validation Test Setup for BMS ALIARO Cell Emulation

The NI Validation Test Setup for BMS using ALIARO Cell Emulation provides a comprehensive environment for testing and validating Battery Management Systems (BMS) under realistic conditions. Leveraging National Instruments' hardware and software ecosystem, this setup emulates individual battery cells with high precision, allowing engineers to simulate various states of charge, temperature conditions, and fault scenarios without the need for actual batteries. The ALIARO cell emulation integrates seamlessly with the BMS, enabling closed-loop testing, real-time monitoring, and automated test sequences. This ensures accurate measurement of voltage, current, and cell balancing performance while evaluating protection mechanisms and system response under abnormal conditions. Scalable, cost-effective solution for research, development, and production testing of next-generation BMS.

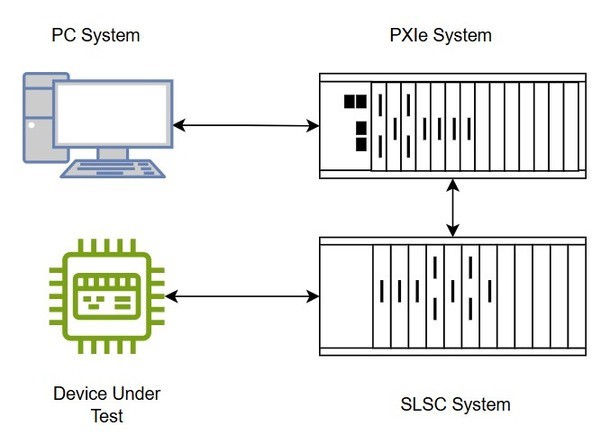

NI PXIe SYSTEMS

Integrated Controller and Chassis

PXIe Chassis Overview: High-performance modular test and measurement platform featuring hybrid backplane for fast inter-module communication. Integrated power, cooling, and controller support for seamless host connectivity. Enables scalable instrumentation setups with reliable performance.

DAQ Module

PXIe I/O Module Overview: Features analog/digital I/O with four 32-bit counter/timers supporting PWM, encoder, frequency, and event counting. High-throughput PCIe bus, NI-DAQmx driver, and configuration utility for simplified setup and operation.

SLSC System

SLSC system provides power, trigger lines, and a digital interface for configuring and controlling SLSC modules. Flexible digital channels can be programmed as inputs or outputs with various drive modes, ensuring reliable signal conditioning for test applications.

List Of Experiments

Motor No-Load Test, Load Performance Analysis without Torque Sensor, System Response to Load Variation and Braking.

Regenerative Braking Simulation and Energy Recovery, Energy Flow Comparison: Grid vs Regen Charging

Battery Charging/Discharging Curve Logging, EV Charging Profile and Energy Utilization

LabVIEW-Based Live RPM, Voltage, and Power Monitoring, Closed-Loop Control of Load Based on Charging Feedback

Safety Analysis, Alerts, and Data Logging System